永久磁鐵、塑胶磁鐵

Hard Ferrite

專業磁鐵、磁石製造供應,歡迎來電洽詢!

TEl:886-4-23860000

E-mail:teslar@ms74.hinet.net

強力磁鐵

NdFeB

專業磁鐵、磁石製造供應,歡迎來電洽詢!

TEl:886-4-23860000

E-mail:teslar@ms74.hinet.net

釤鈷粘結磁鐵

SmCo

專業磁鐵、磁石製造供應,歡迎來電洽詢!

TEl:886-4-23860000

E-mail:teslar@ms74.hinet.net

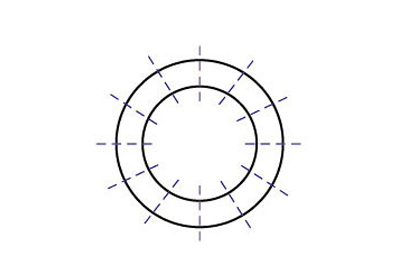

鐵氧體磁鐵

Polar Anisotropic Ferrite Magnet Ring-type

專業磁鐵、磁石製造供應,歡迎來電洽詢!

TEl:886-4-23860000

E-mail:teslar@ms74.hinet.net

鐵氧体極異、鐵氧體燒結磁石

Hard Ferrite Sintered Magnet

專業磁鐵、磁石製造供應,歡迎來電洽詢!

TEl:886-4-23860000

E-mail:teslar@ms74.hinet.net

磁性吸座、磁性吸座

pot magnet

專業磁鐵、磁石製造供應,歡迎來電洽詢!

TEl:886-4-23860000

E-mail:teslar@ms74.hinet.net

輻射取向磁環,以其優良的性能,合理的機構在永磁材料中普遍採用,尤其鐵氧體中使用廣泛。但對於國內燒結釹鐵硼行業來說,充磁方向普遍停留在平行取向水平,輻射取向磁環僅在實驗室試製,還未形成批量供貨能力。

我公司在成型工藝上取得光輝業績的同時,公司繼續加強對產品發展的投入,2003年,本公司科技人員在獨立研製的無等靜壓高度一次成型新工藝基礎上,攻克了輻射取向難題,使國內燒結釹鐵硼生產工藝取得了突破性提高,並於9月28日申請了發明專利(專利號為00125615.7)。目前,此項技術已達到國際先進水準,此項技術的應用在很大程度上推動了釹鐵硼應用領域的擴展。

| 牌號 Item/ 性能 Proprtles | Residual induction 剩磁感應強度 Br mT (kG) |

Coercive Force 矯頑力 bHc KA/m (KOe) | Intrinsic Coercive Force 內稟矯頑力 iHc KA/m (KOe) | Max Energy Product 最大磁能積 (BH)max KI/m3(MGOe) | Max. Appl. Temp. 最高工作溫度 Tw。C |

|---|---|---|---|---|---|

| N35 | 1170-1220 (11.7-12.2) |

≧ 860 ( ≧10.8 ) |

≧ 955 ( ≧12 ) |

263-287 (33-36) |

80 |

| N38 | 1220-1250 (12.2-12.5) |

≧ 860 ( ≧10.8 ) |

≧ 955 ( ≧12 ) |

287-310 (36-39) |

80 |

| N40 | 1250-1280 (12.5-12.8) |

≧ 860 ( ≧10.8 ) |

≧ 955 ( ≧12 ) |

302-326 (38-41) |

80 |

| N42 | 1280-1320 (12.8-13.2) |

≧ 860 ( ≧10.8 ) |

≧ 955 ( ≧12 ) |

318-342 (40-43) |

80 |

| N45 | 1320-1370 (13.2-13.7) |

≧ 860 ( ≧10.8 ) |

≧ 955 ( ≧12 ) |

342-366 (43-46) |

80 |

| N48 | 1370-1430 (13.7-14.3) |

≧ 836 ( ≧10.5 ) |

≧ 876 ( ≧11 ) |

358-390 (45-49) |

80 |

| N50 | 1390-1440 (13.9-14.4) |

≧ 836 ( ≧10.5 ) |

≧ 876 ( ≧11 ) |

374-406 (47-51) |

80 |

| N52 | 1420-1460 (14.2-14.6) |

≧ 836 ( ≧10.5 ) |

≧ 876 ( ≧11 ) |

390-422 (49-53) |

80 |

| N54 | 1450-1490 (14.5-14.9) |

≧ 836 ( ≧10.5 ) |

≧ 876 ( ≧11 ) |

406-437 (51-55) |

80 |

| N55 | 1460-1520 (14.6-15.2) |

≧ 836 ( ≧10.5 ) |

≧ 876 ( ≧11 ) |

414-430 (53-56) |

80 |

| N35M | 1170-1220 (11.7-12.2) |

≧ 868 ( ≧10.9 ) |

≧ 1114 ( ≧14 ) |

263-287 (33-36) |

100 |

| N38M | 1220-1250 (12.2-12.5) |

≧ 899 ( ≧11.3 ) |

≧ 1114 ( ≧14 ) |

287-310 (36-39) |

100 |

| N40M | 1250-1280 (12.5-12.8) |

≧ 923 ( ≧11.6 ) |

≧ 1114 ( ≧14 ) |

302-326 (38-41) |

100 |

| N42M | 1280-1320 (12.8-13.2) |

≧ 955 ( ≧12.0 ) |

≧ 1114 ( ≧14 ) |

318-342 (40-43) |

100 |

| N45M | 1320-1370 (13.2-13.7) |

≧ 995 ( ≧12.5 ) |

≧ 1114 ( ≧14 ) |

342-366 (43-46) |

100 |

| N48M | 1370-1420 (13.7-14.2) |

≧ 995 ( ≧12.5 ) |

≧ 1114 ( ≧14 ) |

358-390 (45-49) |

100 |

| N50M | 1390-1440 (13.9-14.4) |

≧ 995 ( ≧12.5 ) |

≧ 1035 ( ≧13 ) |

374-406 (47-51) |

100 |

| N52M | 1420-1460 (14.2-14.6) |

≧ 995 ( ≧12.5 ) |

≧ 1035 ( ≧13 ) |

382-422 (48-53) |

100 |

| N54M | 1440-1490 (14.4-14.9) |

≧ 995 ( ≧12.5 ) |

≧ 1035 ( ≧13 ) |

398-438 (50-55) |

100 |

| N33H | 1130-1170 (11.3-11.7) |

≧ 836 ( ≧10.5 ) |

≧ 1353 ( ≧17 ) |

247-271 (31-34) |

120 |

| N35H | 1170-1220 (11.7-12.2) |

≧ 868 ( ≧10.9 ) |

≧ 1353 ( ≧17 ) |

263-287 (33-36) |

120 |

| N38H | 1220-1250 (12.2-12.5) |

≧ 899 ( ≧11.3 ) |

≧ 1353 ( ≧17 ) |

287-310 (36-39) |

120 |

| N40H | 1250-1280 (12.5-12.8) |

≧ 923 ( ≧11.6 ) |

≧ 1353 ( ≧17 ) |

302-326 (38-41) |

120 |

| N42H | 1280-1320 (12.8-13.2) |

≧ 955 ( ≧12.0 ) |

≧ 1353 ( ≧17 ) |

318-342 (40-43) |

120 |

| N45H | 1320-1370 (13.2-13.7) |

≧ 995 ( ≧12.5 ) |

≧ 1353 ( ≧17 ) |

342-366 (43-46) |

120 |

| N48H | 1360-1420 (13.6-14.2) |

≧ 1011 ( ≧12.7 ) |

≧ 1273 ( ≧16 ) |

358-390 (45-49) |

120 |

| N50H | 1390-1440 (13.9-14.4) |

≧ 1026 ( ≧12.9 ) |

≧ 1273 ( ≧16 ) |

374-406 (47-51) |

120 |

| N52H | 1420-1460 (14.2-14.6) |

≧ 1035 ( ≧13 ) |

≧ 1273 ( ≧16 ) |

382-422 (48-53) |

120 |

| N30SH | 1080-1130 (10.8-11.3) |

≧ 804 ( ≧10.1 ) |

≧ 1592 ( ≧20 ) |

223-247 (28-31) |

150 |

| N33SH | 1130-1170 (11.3-11.7) |

≧ 844 ( ≧10.6 ) |

≧ 1592 ( ≧20 ) |

247-271 (31-34) |

150 |

| N35SH | 1170-1220 (11.7-12.2) |

≧ 876 ( ≧11 ) |

≧ 1592 ( ≧20 ) |

263-287 (33-36) |

150 |

| N38SH | 1220-1250 (12.2-12.5) |

≧ 907 ( ≧11.4 ) |

≧ 1592 ( ≧20 ) |

287-310 (36-39) |

150 |

| N40SH | 1250-1280 (12.5-12.8) |

≧ 939 ( ≧11.8 ) |

≧ 1592 ( ≧20 ) |

302-326 (38-41) |

150 |

| N42SH | 1280-1320 (12.8-13.2) |

≧ 955 ( ≧12 ) |

≧ 1592 ( ≧20 ) |

318-342 (40-43) |

150 |

| N45SH | 1320-1370 (13.2-13.7) |

≧ 987 ( ≧12.4 ) |

≧ 1512 ( ≧19 ) |

342-366 (43-46) |

150 |

| N48SH | 1360-1400 (13.6-14.0) |

≧ 1011 ( ≧12.7 ) |

≧ 1512 ( ≧19 ) |

358-390 (45-49) |

150 |

| N50SH | 1390-1420 (13.9-14.2) |

≧ 1035 ( ≧13) |

≧ 1512 ( ≧19) |

374-406 (47-51) |

150 |

| N30UH | 1080-1130 (10.8-11.3) |

≧ 812 ( ≧10.2 ) |

≧ 1990 ( ≧25 ) |

223-247 (28-31) |

180 |

| N33UH | 1130-1170 (11.3-11.7) |

≧ 852 ( ≧10.7 ) |

≧ 1990 ( ≧25 ) |

247-271 (31-34) |

180 |

| N35UH | 1170-1220 (11.7-12.2) |

≧ 860 ( ≧10.8 ) |

≧ 1990 ( ≧25 ) |

263-287 (33-36) |

180 |

| N38UH | 1220-1250 (12.2-12.5) |

≧ 907 ( ≧11.4 ) |

≧ 1990 ( ≧25 ) |

287-310 (36-39) |

180 |

| N40UH | 1250-1280 (12.5-12.8) |

≧ 923 ( ≧11.6 ) |

≧ 1990 ( ≧25 ) |

326-302 (38-41) |

180 |

| N42UH | 1280-1320 (12.8-13.2) |

≧ 971 ( ≧12.2 ) |

≧ 1990 ( ≧25 ) |

318-342 (40-43) |

180 |

| N45UH | 1320-1360 (13.2-13.6) |

≧ 987 ( ≧12.4 ) |

≧ 1911 ( ≧24 ) |

342-366 (43-46) |

180 |

| N48UH | 1360-1400 (13.6-14.0) |

≧ 1011 ( ≧12.7 ) |

≧ 1911 ( ≧24 ) |

358-390 (45-49) |

180 | N30EH | 1080-1130 (10.8-11.3) |

≧ 820 ( ≧10.3 ) |

≧ 2388 ( ≧30 ) |

223-247 (28-31) |

200 |

| N33EH | 1130-1170 (11.3-11.7) |

≧ 860 ( ≧10.8 ) |

≧ 2388 ( ≧30 ) |

247-271 (31-34) |

200 |

| N35EH | 1170-1220 (11.7-12.2) |

≧ 884 ( ≧11.1 ) |

≧ 2388 ( ≧30 ) |

263-287 (33-36) |

200 |

| N38EH | 1220-1250 (12.2-12.5) |

≧ 915 ( ≧11.5 ) |

≧ 2388 ( ≧30 ) |

287-310 (36-39) |

200 |

| N40EH | 1250-1280 (12.5-12.8) |

≧ 947 ( ≧11.9 ) |

≧ 2388 ( ≧30 ) |

302-326 (38-41) |

200 |

| N42EH | 1280-1320 (12.8-13.2) |

≧ 970 ( ≧12.2 ) |

≧ 2388 ( ≧30 ) |

318-342 (40-43) |

200 |

| N45EH | 1320-1360 (13.2-13.6) |

≧ 979 ( ≧12.3 ) |

≧ 2308 ( ≧29 ) |

342-366 (43-46) |

200 |

| N28AH | 1020-1090 (10.2-10.9) |

≧ 772 ( ≧9.7 ) |

≧ 2786 ( ≧35 ) |

199-231 (25-29) |

220 |

| N30AH | 1070-1130 (10.7-11.3) |

≧ 812 ( ≧10.2 ) |

≧ 2786 ( ≧35 ) |

215-247 (27-31) |

220 |

| N33AH | 1130-1170 (11.2-11.7) |

≧ 844 ( ≧10.6 ) |

≧ 2786 ( ≧35 ) |

239-271 (31-34) |

220 |

| N35AH | 1170-1220 (11.7-12.2) |

≧ 883 ( ≧11.1 ) |

≧ 2786 ( ≧35 ) |

263-287 (33-36) |

220 |

| N38AH | 1220-1250 (12.2-12.5) |

≧ 915 ( ≧11.5 ) |

≧ 2786 ( ≧35 ) |

287-310 (36-39) |

220 |

| N40AH | 1250-1280 (12.5-12.8) |

≧ 970 ( ≧12.2 ) |

≧ 2706 ( ≧34) |

302-326 (38-41) |

220 |

磁鐵|釹鐵硼強力磁鐵

| Hcj/kOe | (BH)max/MGOe | Temp. max/℃ | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 28 | 30 | 33 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 52 | 54 | 55 | ||

| 40 | (25-29) N28AH (10.2-10.9) |

(27-31) N30AH (10.7-11.3) |

(31-34) N33AH (11.2-11.7) |

(33-36) N35AH (11.7-12.2) |

(36-39) N38AH (12.2-12.5) |

(38-41) N40AH (12.2-12.8) |

220 | |||||||

| 35 | (28-31) N30EH (10.8-11.3) |

(31-34) N33EH (11.3-11.7) |

(33-36) N35EH (11.7-12.2) |

(36-39) N38EH (12.2-12.5) |

(38-41) N40EH (12.2-12.8) |

(40-43) N42EH (12.8-13.2) |

(43-46) N45EH (13.2-13.6) |

200 | ||||||

| 30 | (28-31) N30UH (10.8-11.3) |

(31-34) N33UH (11.3-11.7) |

(33-36) N35UH (11.7-12.2) |

(36-39) N38UH (12.2-12.5) |

(38-41) N40UH (12.2-12.8) |

(40-43) N42UH (12.8-13.2) |

(43-46) N45UH (13.2-13.6) |

(45-49) N48UH (13.6-14) |

180 | |||||

| 25 | (28-31) N30SH (10.8-11.3) |

(31-34) N33SH (11.3-11.7) |

(33-36) N35SH (11.7-12.2) |

(36-39) N38SH (12.2-12.5) |

(38-41) N40SH (12.5-12.8) |

(40-43) N42SH (12.8-13.2) |

(43-46) N45SH (13.2-13.7) |

(45-49) N48SH (13.6-14) |

(47-51) N50SH (13.9-14.2) |

150 | ||||

| 20 | (31-34) N33H (11.3-11.7) |

(33-36) N35H (11.7-12.2) |

(36-39) N38H (12.2-12.5) |

(38-41) N40H (12.5-12.8) |

(40-43) N42H (12.8-13.2) |

(43-46) N45H (13.2-13.7) |

(45-49) N48H (13.6-14.2) |

(47-51) N50H (13.9-14.4) |

(48-53) N52H (14.2-14.6) |

120 | ||||

| 17 | (33-36) N35M (11.7-12.2) |

(36-39) N38M (12.2-12.5) |

(38-41) N40M (12.5-12.8) |

(40-43) N42M (12.8-13.2) |

(43-46) N45M (13.2-13.7) |

(45-49) N48M (13.6-14.2) |

(47-51) N50M (13.9-14.4) |

(48-53) N52M (14.2-14.6) |

(50-55) N54M (14.4-14.9) |

100 | ||||

| 14 | (33-36) N35 (11.7-12.2) |

(36-39) N38 (12.2-12.5) |

(38-41) N40 (12.5-12.8) |

(40-43) N42 (12.8-13.2) |

(43-46) N45 (13.2-13.7) |

(45-49) N48 (13.6-14.3) |

(47-51) N50 (13.9-14.4) |

(49-53) N52 (14.2-14.6) |

(51-55) N54 (14.5-14.9) |

(53-56) N55 (14.6-15.2) |

80 | |||

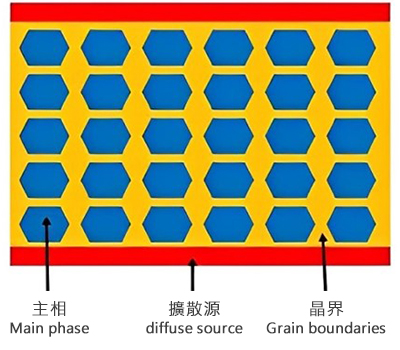

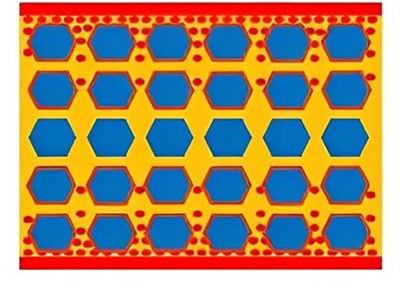

晶界擴散(Grain boundary diffusion,“GBD”) 技術是近幾年發展起來的一種可以有效改善燒結釹鐵硼磁體磁性能的技術手段。通過在磁鋼表面形成一層重稀土膜,經真空熱處理使重稀土沿晶界進入磁體內部,同時重稀土原子取代主相晶粒周圍的Nd 原子形成高矯頑力殼層,這種獨特的顯微結構在極低的剩磁下降值基礎上可大幅提升磁體矯頑力。

Grain boundary diffusion(GBD) technology is a technical means developed in recent years that can effectively improve the magnetic properties of sintered NdFeB magnets.By forming a layer of heavy rare earth film on the surface of the magnet, the heavy rare earth enters the interior of the magnet along the grain boundaries through vacuum heat treatment. At the same time, the heavy rare earth atoms replace the Nd atoms around the main phase grains to form a high coercive force shell. This unique The microstructure greatly increases the magnet's coercive force with extremely low Br loss.

與傳統的非擴散磁體NdFeB相比較,晶界擴散工藝的主要優勢體現在:

*由於濃度梯度的存在,擴散深度受限,故規模量產的擴散磁鋼厚度通常會有一定的限制。

Compared with the traditional non-diffusion magnet NdFeB, the main advantages of the grain boundary diffusion process are reflected in:

*Due to the existence of concentration gradient, the diffusion depth is limited, so the thickness of diffusion magnet steel for large-scale mass production usually has certain limitations.

| 牌號 Item/ 性能 Proprtles | Residual induction 剩磁感應強度 Br mT (kG) |

Coercive Force 矯頑力 bHc KA/m (KOe) | Intrinsic Coercive Force 內稟矯頑力 iHc KA/m (KOe) | Max Energy Product 最大磁能積 (BH)max KI/m3(MGOe) | Max. Appl. Temp. 最高工作溫度 Tw。C |

|---|---|---|---|---|---|

| G55H | 1470-1525 (14.7-15.25) |

≧ 1106 ( ≧13.9 ) |

≧ 1353 ( ≧17 ) |

414-446 (52-56) |

120 |

| G57H | 1495-1550 (14.95-15.5) |

≧ 1122 ( ≧14.1 ) |

≧ 1353 ( ≧17 ) |

430-462 (54-58) |

120 |

| G48SH | 1370-1420 (13.7-14.2) |

≧ 1011 ( ≧13 ) |

≧ 1592 ( ≧20 ) |

358-390 (45-49) |

150 |

| G50SH | 1400-1450 (14.0-14.5) |

≧1027 (≧13.2) |

≧1592 (≧20) |

374-406 (47-51) |

150 |

| G52SH | 1420-1480 (14.2-14.8) |

≧1067 (≧13.4) |

≧1592 (≧20) |

390-422 (49-53) |

150 |

| G55SH | 1460-1510 (14.6-15.1) |

≧1083 (≧13.6) |

≧1592 (≧20) |

406-438 (51-55) |

150 |

| G40UH | 1255-1305 (12.55-13.05) |

≧939 (≧11.8) |

≧1990 (≧25) |

302-326 (38-41) |

180 |

| G42UH | 1285-1335 (12.85-13.35) |

≧963 (≧12.1) |

≧1990 (≧25) |

318-342 (40-43) |

180 |

| G45UH | 1330-1380 (13.3-13.8) |

≧978 (≧12.4) |

≧1990 (≧25) |

334-366 (42-46) |

180 |

| G48UH | 1370-1420 (13.7-14.2) |

≧1027 (≧12.9) |

≧1990 (≧25) |

358-390 (45-49) |

180 |

| G50UH | 1400-1450 (14.0-14.5) |

≧1051 (≧13.2) |

≧1990 (≧25) |

374-406 (47-51) |

180 |

| G52UH | 1420-1480 (14.2-14.8) |

≧1067 (≧13.5) |

≧1990 (≧25) |

390-422 (49-53) |

180 |

| G54UH | 1460-1510 (14.6-15.1) |

≧1075 (≧13.5) |

≧1990 (≧25) |

406-438 (51-55) |

180 |

| G35EH | 1170-1220 (11.7-12.2) |

≧883 (≧11.1) |

≧2388 (≧30) |

263-287 (33-36) |

200 |

| G38EH | 1220-1270 (12.2-12.7) |

≧916 (≧11.5) |

≧2388 (≧30) |

287-310 (36-39) |

200 |

| G40EH | 1260-1310 (12.6-13.1) |

≧955 (≧12.0) |

≧2388 (≧30) |

302-334 (38-42) |

200 |

| G42EH | 1270-1335 (12.7-13.35) |

≧955 (≧12.0) |

≧2388 (≧30) |

310-342 (39-43) |

200 |

| G44EH | 1290-1350 (12.9-13.5) |

≧971 (≧12.2) |

≧2388 (≧30) |

318-350 (40-44) |

200 |

| G45EH | 1320-1380 (13.2-13.8) |

≧995 (≧12.5) |

≧2388 (≧30) |

334-366 (42-46) |

200 |

| G46EH | 1330-1380 (13.3-13.8) |

≧1011 (≧12.7) |

≧2388 (≧30) |

334-366 (42-46) |

200 |

| G48EH | 1370-1420 (13.7-14.2) |

≧1027 (≧12.9) |

≧2388 (≧30) |

358-390 (45-49) |

200 |

| G50EH | 1400-1450 (14.0-14.5) |

≧1051 (≧13.2) |

≧2388 (≧30) |

374-406 (47-51) |

200 |

| G35AH | 1170-1220 (11.7-12.2) |

≧891 (≧11.2) |

≧2786 (≧35) |

263-287 (33-36) |

220 |

| G38AH | 1220-1270 (12.2-12.7) |

≧931 (≧11.7) |

≧2786 (≧35) |

287-310 (36-39) |

220 |

| G40AH | 1240-1305 (12.4-13.05) |

≧947 (≧11.9) |

≧2786 (≧35) |

295-326 (37-41) |

200 |

| G42AH | 1270-1335 (12.7-13.35) |

≧963 (≧12.1) |

≧2786 (≧35) |

310-342 (39-43) |

220 |

| G45AH | 1320-1380 (13.2-13.8) |

≧995 (≧12.5) |

≧2786 (≧35) |

334-366 (42-46) |

220 |

磁鐵|釹鐵硼強力磁鐵

| Hcj/kOe | (BH)max/MGOe | Temp. max/℃ | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 35 | 38 | 40 | 42 | 45(46) | 48 | 50 | 52 | 54(55) | 57 | |||

| 40 | (33-36) G35AH (11.7-12.2) |

(36-39) G38AH (12.2-12.7) |

(37-41) G40AH (12.4-13.05) |

(39-43) G42AH (12.7-13.35) |

(42-46) G45AH (13.2-13.8) |

220 | ||||||

| 35 | (33-36) G35EH (11.7-12.2) |

(36-39) G38EH (12.2-12.7) |

(38-42) G40EH (12.6-13.1) |

(39-43) G42EH (12.7-13.35) |

(42-46) G46EH (13.3-13.8) |

(45-49) G48EH (13.7-14.2) |

(47-51) G50EH (14.0-14.5) |

200 | ||||

| 30 | (38-41) G40UH (12.55-13.05) |

(40-43) G42UH (12.85-13.35) |

(42-46) G45UH (13.3-13.8) |

(45-49) G48UH (13.7-14.2) |

(47-51) G50UH (14.0-14.5) |

(49-53) G52UH (14.2-14.8) |

(51-55) G54UH (14.6-15.1) |

180 | ||||

| 25 | (45-49) G48SH (13.7-14.2) |

(47-51) G50SH (14.0-14.5) |

(49-53) G52SH (14.2-14.8) |

(51-55) G55SH (14.6-15.1) |

150 | |||||||

| 20 | (45-49) G48H (13.6-14.2) |

(47-51) G50H (13.9-14.4) |

(48-53) G52H (14.2-14.6) |

(52-56) G55H (14.7-15.25) |

(54-58) G57H (14.95-15.5) |

120 | ||||||